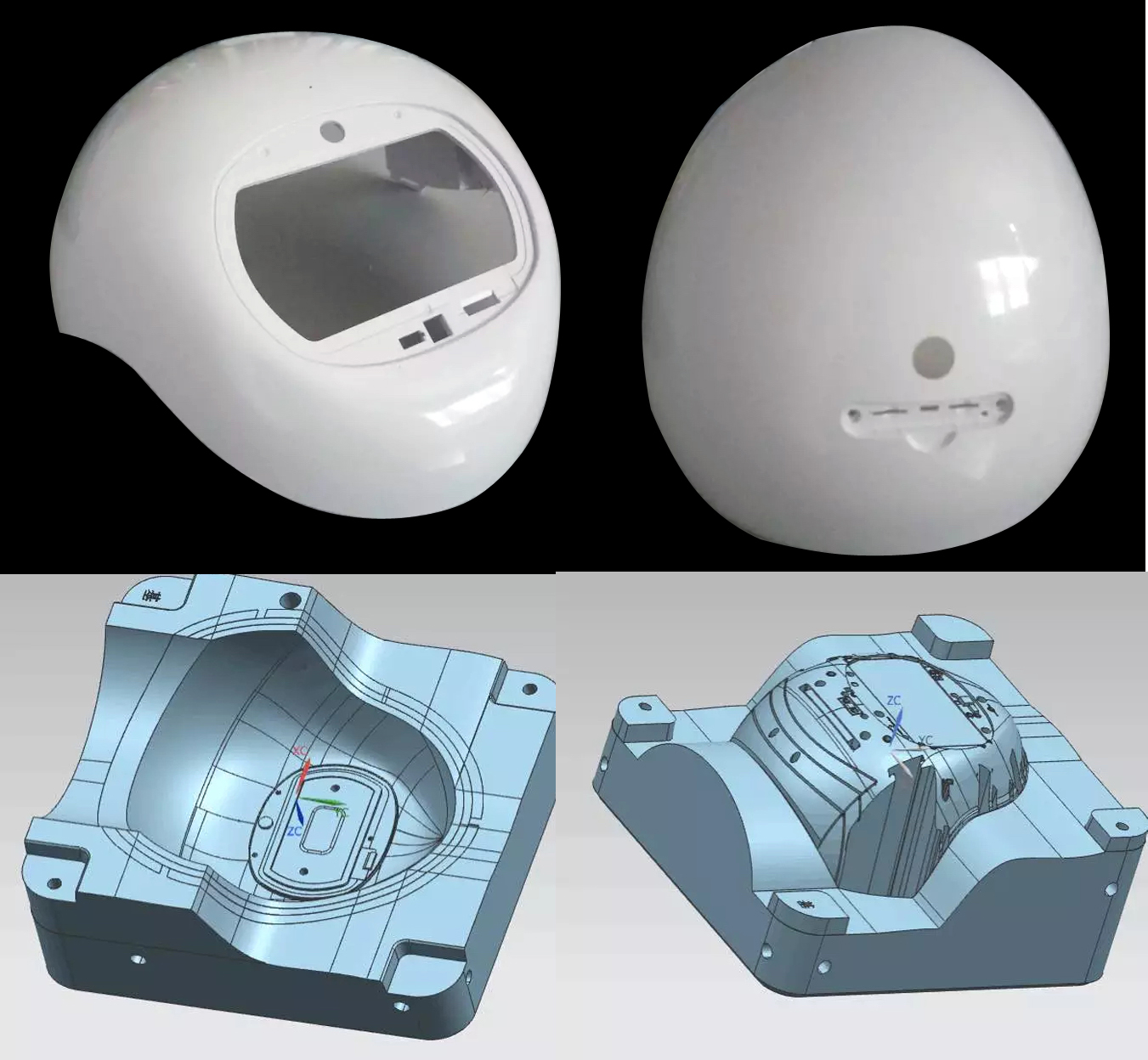

Mould Manufacturing & Plastic Injection:

---- Finish: Matte, Polished, Textured , EDM, laser etching, Chrome plating .

---- As our second key service , Pro-Precise owns more than 30 injection machines which able to produce products unit weight from 0.5g to 2500g .

Pro-Precise ‘s mold products covers the automotive industry, medical equipment, electronic products case, household appliances, LED lighting shell industry. we work with our customers who mostly from USA and Europe to establish close busininess relationship, we fully understand the needs of customers. We particularly welcome in bee team custom mold and meanwhile in the production of injection molded parts .

Long term production experience allows us to summarize several key factors of high quality molds :

1, Plastic parts structure analysis

We will rule out some basic design problems, such as the draft and texture can be meet at the sametime . If the parting line ,gate position and type & ejector pin will affects the appearance of the parts,

2, Senior designer

Our mold designer has 10 years designing experience, we are not only to ensure the mold structure reasonable, but also fully consider the quality stability for long-term production ,cooling, exhaust, stress and other hidden problems.

3, high-quality mold parts and die steel

We insist to use high-quality mould parts and die steel material .

4, standardized production processing

5, standard production sample report, mass prodution test report

6, Mould designing drawing provided before the trial after order comfirmed

Copyright © XiaMen EPRO Technology Co., Ltd. All Rights Reserved.